Manufacturing of steel structures

OUR WORK PROCESS

Integral manufacturing of steel structures with guaranteed deadlines

The manufacturing of steel structures at Jansa Metal follows our own precise and fully controlled process, which allows us to deliver each structure ready for assembly and on time.

A unique workflow that delivers your structure ready for assembly, meeting every deadline with precision.

📞 Request your technical appointment and get started without delays

1. Analysis

We receive your order and treat it as a challenge.

We review similar cases from our archive, select the most reliable solutions, and present alternatives to the client or site management (dirección facultativa).

2. Solution and Proposal

Economic Proposal + Graphical Schemplan.

We calculate and quantify the chosen options (economy vs. speed vs. durability) so that you can make a decision with full visibility.

3. Detail Engineering

Once the order is approved, detail engineering begins: the structure is recalculated and connections are developed according to Eurocodes. The IFC model is then generated, accompanied by the justification calculation report for site management to review and validate.

4. Production Order

Once the IFC model is validated, the model is finalized and the manufacturing file is generated according to the required execution level: listings and NC (Numerical Control) files, general drawings, sections, piece-by-piece drawings, anchoring, and assembly.

5. Procurement Management

During the engineering and validation phase, stock and lamination alternatives are analyzed and compared with suppliers to ensure that materials arrive according to the production schedule.

6. Receipt and Classification

Materials are received and verified, and certificates are registered to ensure traceability. Batches are classified according to the required surface treatment.

7. Treatment

After material receipt and classification, the batches are sent to the shot-blasting and shop-primer line or are labeled for manufacturing and the chosen treatment. Depending on the project,

8. Fabrication of welded plate girders (built-up sections)

We produce Welded Built-Up Sections (WBS) on the automatic JUWELD – TwinArc line (double-wire submerged arc process). This system allows for

9. NC Machining

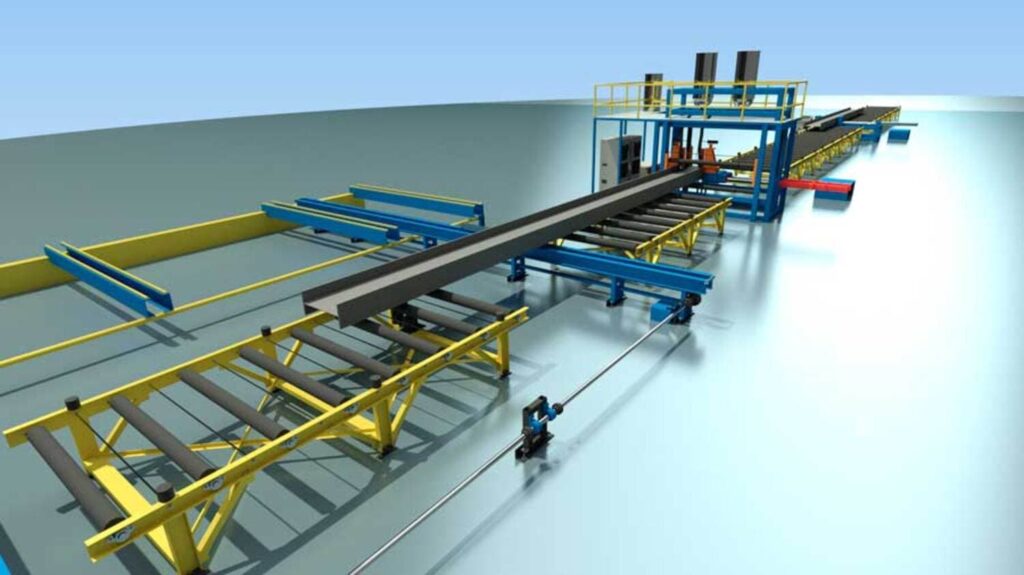

Material batches per project arrive via the roller and transfer system to the cutting and drilling lines. They proceed to cutting and drilling: profiles ≤ 350×350 mm (up to 12 m) by CNC laser, and the rest by

10. Fabrication and Control

The machined parts are assembled in the fabrication area, operating in two shifts (6:00 – 22:00). Following the production system and the order’s execution level, spot checks are carried out, and all parts are labeled with a metal plate engraved with the job number and the shipping piece number.

11. Welding and Control

The identified parts are welded according to the welding plan and production order. Dimensional controls, penetrant testing (liquids), and ultrasonic testing are performed.

12. Final Finish

After welding, the chosen paint system and RAL color are applied. The metal labels ensure the traceability of each component.

13. Packaging and Strapping

Once painting and drying time are complete, the pieces are prepared in batches by delivery order and strapped, awaiting loading.

14. Loading and Transport

National or international transport by truck or container is coordinated.

15. On-site Receipt

The unloading and condition of the materials on-site are supervised. We verify that the assembly area is clear according to the planning communicated to the client. The pieces are then strategically stockpiled and the necessary team and means are organized, allowing a 10,000 m² warehouse to be assembled in just 2 weeks with a team of 5 people.

16. Setting-out Certificate (Acta de Replanteo)

Before starting assembly, Jansa Metal performs the Preliminary Setting-out Certificate: inspection of the anchors placed by the contractor before concreting to verify their correct positioning. After concreting, the Final Setting-out Certificate is issued to check that the anchors maintain the necessary position and level reservation for leveling.

17. Assembly

Assembly is carried out by teams of 3, with 2 aerial work platforms and a mobile crane; the number of teams and resources will depend on point 15.

18. Reception Certificate

Once assembly is finished, we conduct an exhaustive review with the client and/or site management, and the acceptance certificate is issued. Jansa delivers the CE Mark report and the Declaration of Performance according to EN 1090.

Other services

you’ll be interested in

At Jansa Metal, we offer comprehensive solutions for the manufacturing of metal structures, optimizing every process to ensure quality, strength, and efficiency.

Discover more about our services, from shot blasting and painting to PRS beam manufacturing and structural assembly.

FAQ’s

Ready for the First Step? Contact us!

Every great project starts with a conversation. Contact us and find out how we can bring your idea to reality, with metal structures that are as solid as your expectations.